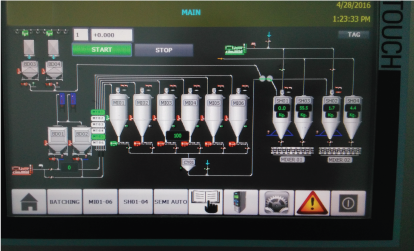

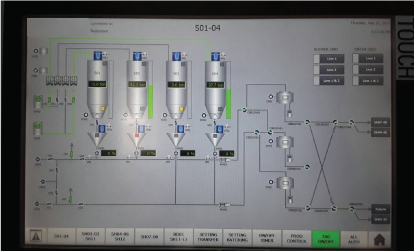

Pneumatic Conveying System

The material conveying system, as part of our process technology,will be designed based on good engineering principles and tailored to the needs of the Client as much as possible – taking into consideration the whole process chain from receiving and Storage (Silo / Big Bag / Bag

Dumping Station), Sifting, Weighing as well as recipe control. All these stages will be designed by the Engineering Department of Con-Mix to be convenient and easy to operate and fully efficient and functional, as previously illustrated in the diagram.

Storage & Discharge

Raw materials should be stored with regard to their individual physical and chemical properties in order that quality of the end product will not be degraded. FIFO or First In, First Out principle is the underlying concept in process technology design for silo and storage hopper.

At the same time, it is vital to ensure hygienic design of all equipment parts and avoidance of any cross-contamination. Also, such process parameters as humidity, temperature and maximum storage time should be constantly monitored and controlled. To ensure consistent production quality, we recommend monitoring all process parameters using State of the Art precision sensor technology and control system.

Conveying

Con-Mix provides conveying systems that can be tailored to meet the client’s specific requirement – ranging from slow-speed system for gentle product handling to conventional dilute phase (vacuum and pressure system) conveying system.

Vacuum System

The vacuum system will require negative pressure in order to pull the material through the conveying line. Then, the material will be dropped by the gravity to the receiving hopper, and the air without dust will be remove through the dust collector to protect the vacuum generator.

The vacuum system is usually preferred for transporting free-flowing, nonabrasive materials. However, this type of system is not suitable for materials that must be transported over a long distance.

Pressure System

The pressure system will require positive pressure and it can be adjusted to be the dense phase with low pressure or dilute phase. In this system, the feeding equipment will convey the materials into the pressure vessel. After the vessel is full, the high-pressure air discharges the material into the conveying line and conveys it to the receiver where the dust collector will separate the material from the air.

This type of conveying system is generally preferred for transporting a heavier material over a longer distance.

Sifting

Remove coarse granules and aerate the raw materials for better processing and protection of equipment downstream. The sifters that we offer have all parts in contact with the product constructed to meet food quality guidelines. Depending on throughput capacity, location space and type of material, sifters of various sizes are available.

Sifter A

In-Line Sifting

As the In-Line sifters are inserted directly into the pneumatic conveying system for removal of oversized impurities, there is no need to switch to (atmospheric pressure) gravity flow sifting and back to pneumatic again.

Thus, saving a great deal of both initial investment cost and subsequent operating, maintenance and sanitation costs throughout the system’s life. Another important benefit of In-Line sifting is that it enables sifting protection to be placed close to the finished product, minimizing contamination from any extra equipment after sifting.

The In-Line sifter works like a multi-sieve gravity-flow sifter except that it operates at the pressure or vacuum of the pneumatic conveying line. An air bypass arrangement equalizes the air pressure above and below the sifting screens. Thus, no force other than gravity causes the product to fall through the screens.

The product enters at the top center, passes through screens and is discharged to side channels. Oversized particles end up in a sealed tailings canister at the bottom of the sifter.

Sifter B

Rotary sifters

High-quality rotary sifters for food, chemical, plastic processing and pharmaceutical industry as well as for small industrial bakeries. The compact, sturdy, rotary sifters, operating on the proven rotation principle, have all parts in contact with the product constructed not only to meet food quality guidelines of the European Hygienic Engineering & Design Group and BG regulations but also designed for easy cleaning.

The feeding screw and beater bars are equipped with double bearings and sealed from the product area with additional sealing rings. The sifter screens are made of polyester or polyamide. When used as an in-line sifter, it can be connected directly into the pressure or vacuum conveying line for a pressure tight operation of up to 0.8 bar or vacuum pressure.

Depending on throughput capacity, location space and type of material, sifters of various sizes are available.

The machine housing and inner components are made of stainless steel and inlet housing and cover are made of cast aluminum alloy.

Whichever model, the sifter continuously breaks up clumps, removes coarse granules and aerate the raw materials for better processing and protection of equipment downstream. A pressure hopper for cleaning of

the sifter drum is optionally available.

Weighing & Metering

Our intelligent process technology can deal equally well with batch or continuous process – manual or fully automated operation – as the user requires.

We can provide a choice of measurement and degree of accuracy that the client specifies. Whether the client requires precise recipe processing of micro ingredients, especially in the food industry, or simply bulk mixing, we can provide excellent metering systems to best meet the client’s needs.

The technology that we offer has a long track record of successful production systems to back up its reputation of reliable, trouble-free continuous operation. Moreover, the system models available for storage and metering of products with different characteristics can be used either as a standalone or integrated into an existing production system.

A basic manual design for storage and recipe metering of dry ingredients features manual filling and manual removal with weighing on recipe controlled scale.

We take a holistic approach to each processing requirement and are ready to provide drying, humidifying, temperature control, homogenising, sifting, mixing, grinding and recrystallizing of the materials as required.