Batching System

Generally

SIM (Single Ingredient Metering System). Manual weighing of raw material can be troublesome, time-consuming and prone to error. Aware of the problem face by our clients, Con-Mix engineers have developed Automatic Ingredient Metering System (AIM) to perform the task automatically, efficiently and reliably, eliminating any human error.

Function

- Supports continuous weighing operation.

- With our smart system, every batch will be controlled and recorded exactly as its setting.

- Friendly Human Machine Interface (HMI) via multi- touch screen control panel.

- Increase efficiency with our automatic cleaning system using JET FILTER.

- Equipped with Lump Breaker Device to break up lumps of raw material (Option).

Inventory record.

System Specification

| Dimensions | 1500 (W) x 3000 (L) x 3800 -7000 (H) mm. |

| Product | Material in powder form (Granulated sugar, wheat flour or other) |

| Practical size | 425 – 1500 µm (or adaptable as required) |

| Sieve size | 425 – 1500 µm (or adaptable as required) |

| Capacity | > 60 bags / hour (or adaptable as required) |

| Accuracy | 0.5% standard (or specified by client) |

| Power supply | 380 Volt/50-60 Hz |

| Compressed air | 5-7 bar |

| Material structure | Stainless steel/ SUS304 Grade |

| Control panel | Siemens PLC with touch screen comfort panel |

Generally

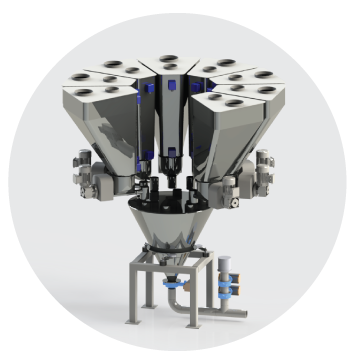

MIM (Multi-Ingredient Metering System) is design for material storage and retention of recipes for weighing dry materials, or a secondary ingredient, in the production process.

Surface in contact with the product are designed to fit the standards of food production to ensure the quality and efficiency of the manufacturing process.

Function

- The system is designed to record and store a large number

of production recipes as may be required by client. - Convenient and easy to operate.

- Metering in a closed system, diffusion of dust is prevented.

- The storage environment is controlled.

- Automatic raw material inventory control.

- High accuracy and precision.

System Specification

| Dimensions | 1500 (W) x 3000 (L) x 3800 -7000 (H) mm. |

| 10 ingredient hoppers (standard), extendable as required by the client | |

| Machine parts in contact with product: stainless steel 304 | |

| 500 L ingredient hopper capacity; larger sizes can be specified by the client | |

| Central scale weighing system | |

| 25 Kg Maximum weighing capacity; can be increased as required | |

| Weighing precision is 0.5% (or specified by the client) | |

| Capacity | > 60 bags / hour (or adaptable as required) |

| Accuracy | 0.5% standard (or specified by client) |

| Power supply | 380 Volt/50-60 Hz |

| Compressed air | 5-7 bar |

| Material structure | Stainless steel/ SUS304 Grade |

| Control panel | Siemens PLC with touch screen comfort panel |

Screw feeder

The device can be applied universally and used as a single station or in combination with several devices. The feeder needs no maintenance and is lubricated for its lifetime. The feeder is designed in such a way that several options such as gas-filled seals, dust proofing, and extension of spiral and outlet tubes, seals of various materials may be adopted without problems.

In designing our device, we paid particular attention to its FDA suitability. We only use seals with an FDA certificate. Steel parts in contact with the product are made of stainless steel 1.4404 (1.4435).

A Gain-in-Weight (GIW) batching station

Includes volumetric metering devices, such as screw feeders or valves that deliver the product to a hopper on load cells.

The Loss-in-Weight (LIW) batching system

Employs gravimetric feeding devices, such as

loss-in-weight screw or vibratory feeders, which are

mounted on individual load cells or scales. In cases

where small amounts of micro ingredients are required,

both methods may be employed: LIW feeders for

the micros and minors, and GIW batch for the major

ingredients.

Selection of applications

Food industry

- Dairy powders

- Flour/bakery

- Ingredient/noodles

- Instant drinks

- Seasoning

Feed industry

- Animal feed

- Pet food

Chemical industry

- Resin

- Color pigments

System Specification

| Description | Model | Features | Feed Rate (L/hr) | Hopper Volume (Liter) | Feed Accuracy |

| CMF-T18 | GIW,LIW | 12-120 | 20 | 0.1%,0.2% | |

| CMF-T28 | GIW,LIW | 50-500 | 80 | 0.1%,0.2% | |

| CMF-ZD 32 B | GIW,LIW | 50-200 | 200 | 0.1%,0.2% | |

| Screw Feeder | CMF-T38 | GIW,LIW | 80-800 | 200 | 0.1%,0.2% |

| CMF-ED 55 B | GIW,LIW | 150-2500 | 200 | 0.1%,0.2% | |

| CMF-ED 55 FB | GIW,LIW | 150-2700 | 200 up | 0.1%,0.2% | |

| CMF-T78 | GIW,LIW | 400-4000 | 200 up | 0.1%,0.2% |